A simple project of creating a CAD model of a Swedish fish. This is more of a silly than practical project, but was generated because of the excitement I got when someone in MITERS mentioned McMaster had Swedish fish drawings.

If you have ever had to deal with moving large and heavy objects, you may have come to appreciate the value of a good lever. When it comes moving heavy equipment, nothing quite beats the stout johnson bar. In this project I set out to refurbish two johnson bars purchased at auction.

In MITERS we have a tradition of building electric vehicles and riding them around campus/cambridge for fun. This projects goal was to create a comfortable, peppy, and robust electric trike while also limiting its top speed for safety.

In the earlier part of the pandemic I was able to find a pneumatic surface grinder and bandsaw at an industrial auction (Online) in waltham, MA. What I didn't realize at the time of purchase was just how good a bandsaw could be... let alone a $40 one.

In my opinion a key component in setting the feel for a hacker space is the sign. I finally made a decision to build a sign for MITERS that lives up to the space and the projects that are made there.

Recently I came across some decent and rusty cast iron at a junk-yard and was able to pick it all up for $5. So I decided to re-season it from scratch because I had no idea what the history of the cast iron was (and what it had come into contact with). I also decided to take the time to also re-do my favorite cast-iron skillet from Kinsers, PA.

I wanted to create a personal gift for a friend, roughly from scratch, and I decided to create a picture frame.

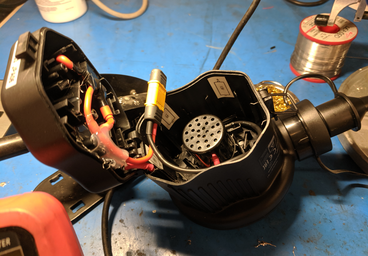

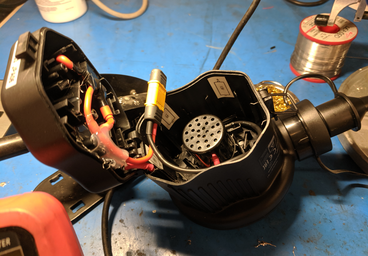

When working on another project I came across an issue with the tooling at MITERS. Our only MITERS saw was battery powered... but in the last year we threw away all our old tool batteries and standardized. So none of the batteries fit the MITERS Saw. That's when I decided to shift gears and focus on making the MITERS saw run off any of our D.C. Power supplies.

This project was centered around a junk-yard find, a battery powered Quick-fill device for inflating inflatables. The goal was to improve its ability to quickly fill an inflatable raft using high discharge lithium instead of C-cell batteries.

Every professional has a high quality item related to their field of study or work. This item both holds significance to themselves but also to their jobs. Along these lines, as an experimental physicist and tinkerer, I have decided to create a personalized custom case for a set of engineering tools: Mitutoyo 6" Calipers, Metric and English screw pitch gauges, small Fillet and Radius gauges, and large fillet and radius gauges. All but the calipers are vintage Starrett tooling made in Massachusetts, purchased from Ebay and Refurbished.

In this project my goal was to replicate a simple wooden coat rack into a more sturdy all metal construction.

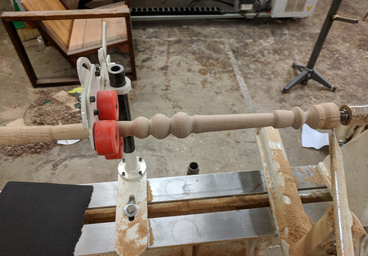

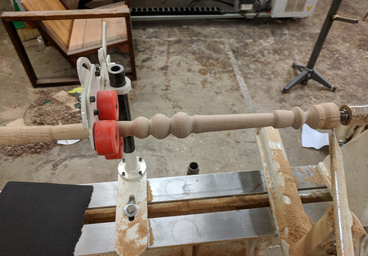

This projects objective is to create a short-staff based off of the staff of the main character from the popular cartoon Craig of the Creek. This staff was a present for my roommate who loves the show and has gotten me into the show. The staff created will be from scratch.

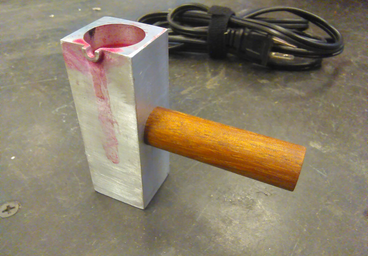

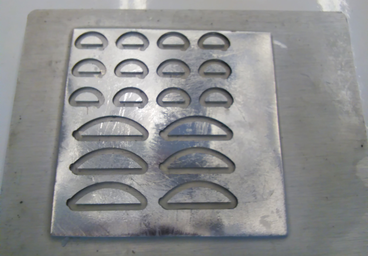

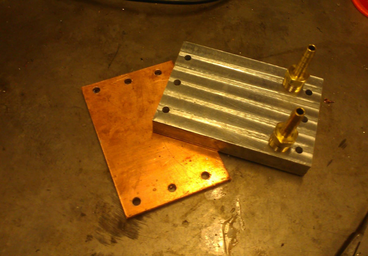

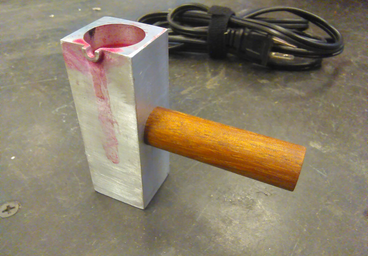

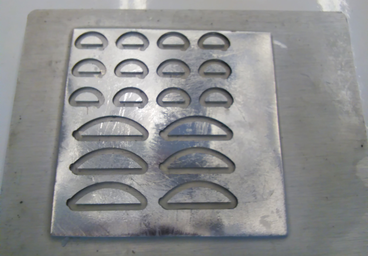

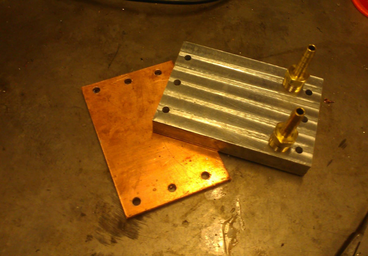

Creating a custom tool set for my friend who blows glass at MIT Glass Lab. The tools built are for making precise holes for (1) corks in custom bottles and (2) creating glass candle stick holders.

My first heat-cartridge wax pot died due to the solid metal wire getting pinched and sheered. This project is my attempt at taking all the lessons I learned from my first wax-pot and creating a more robust and useful design.

This project had a simple goal, create a custom steel pulley for my friends Barber Colman no. 3 gear-hobbing machine.

Fabrication of a custom cam profile for use in machine automation.

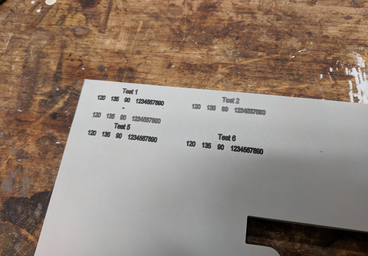

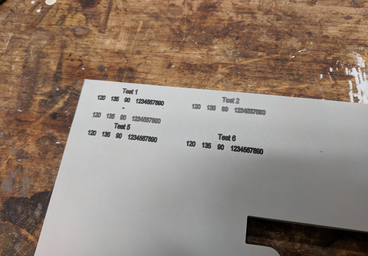

General Tests done to determine optimal settings for Cermark LMM-6000 with a 120W Epilog CO2 laser.

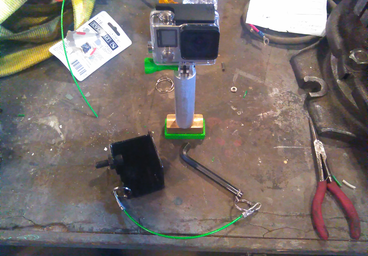

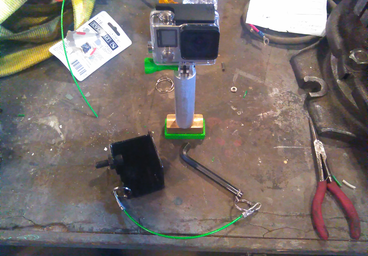

Fabricate accessories for my new GoPro(refurbished Gopro Hero 4 - Ebay) to expand what I can do with it.

Making decent modular shelves and side tables using cheap home depot boards, threaded rod, washers, and nuts.

Using Shapeways 3D Printing services to create vacuum comparable holders for our SBD's (Surface Barrier Detector) in the vacuum chamber of the HEDP Particle Accelerator.

"Carving Pumpkins at Peter's Halloween Party using a high powered laser."

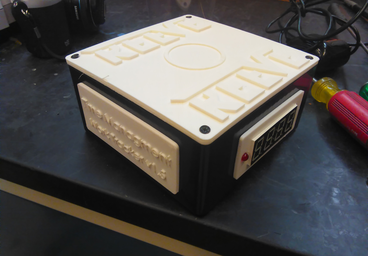

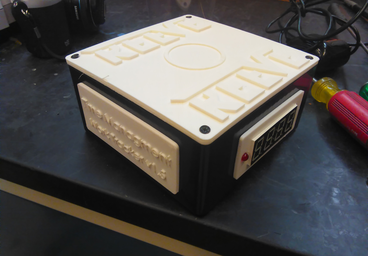

A friend of mine has been finding himself losing track of time at work and thus working way more than his 40 hours a week. This projects aim is to create a standalone box that will actively track his time at work each week.

This is work I did to support the research efforts of the pProbeJet Omega campaign @ LLE. The purpose of the proposed research was to measure the effects of the ambient gas on a plasma jet propagation. This was done using two separate diagnostics to produce images of the plasma jets at different time periods, different gasses, and different pressures.

To clean out an older thrown out gear reducer, replace the gaskets, and fill with new oil.

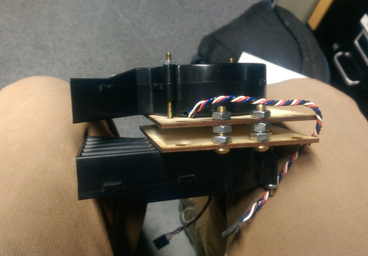

To create a durable force air system for two Intel Xeon Phi's, to help keep them from overheating. [Xeon Phi Info link]

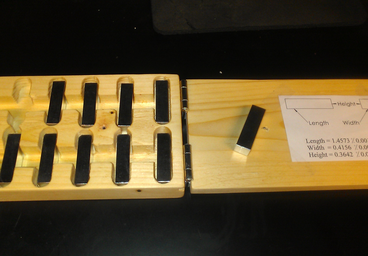

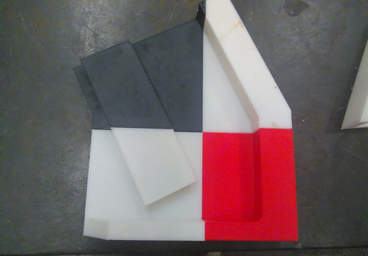

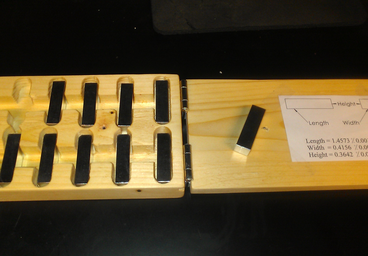

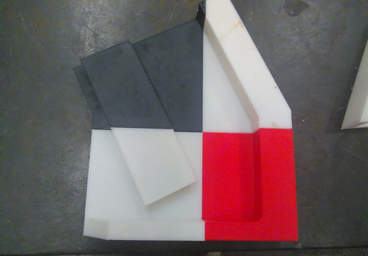

This project was aimed at creating multiple cuboids of roughly identical size for a Physics undergraduate course.

Design and fabrication of a cocktail glass that takes its inspiration from the Atomic Cocktail (drink, song, and Fallout in-game item).

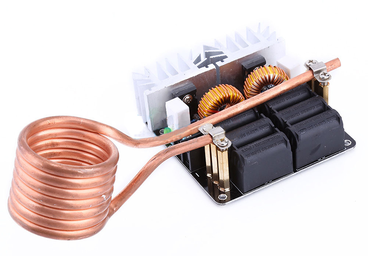

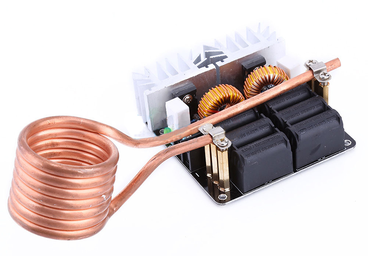

Creating a experimental setup designed around a Chinese induction heater which allows for the insertion of alumina crucibles.

Creating components for a group electric bike trip up the white mountains. 3D Go-Pro Cube that allows you to take 360 video with multiple go-pros. Bike Phone Holders for data logging.

"To create a better way to melt enough wax to create a wax seal with my custom bronze seal."

One of our friends and MITERS members was heading off to the great big California Tech Region, and we decided we need to have a cake... so we baked one in MITERS with light!!!

A friend is moving into a new space where he setup a few machines, and every shop space needs a door bell. So I decided to refurbish a working xylophone door bell, with a bit of customization.

"Manufacturing scintillation material into specific shapes for a diagnostic package run at The Laboratory for Laser Energetics (LLE) Omega Facility."

A brief selection of some recent 3D printing projects I did in MITERS.

Refurbishing an old Belknap Bluegrass double-headed axe that I bought for $20 at Kinzers Rough and Tumble Tractor Show flea market in Pennsylvania.

The goal of this project was to convert a gas-powered trolling motor into an electric powered one within a night.

"My Father gave me our old milkshake machine I grew up with as a christmas present. The goal of this project was to clean it up

"The project was aimed to create a reliable system in which MIT students could find-out if the MIT Electronic Society (MITERS) was currently open.

The project is aimed to replace my current battery powered lights for my bike with a dedicated power system with more capacity and durability.

This project was aimed at creating a testing apparatus that allows you to vary the temperature between (Below Freezing)to ~100F.

This project came out of the desire to build new things for my upcoming move and to work with wood for a change. So the project was aimed at creating a quality cutting board at an affordable price.

This project was designed around the use of the CNC Mill that has recently been added to the MITERS arsenal of machines. The project involves using the CNC mill to machine precise design into a piece of brass cylindrical stock.

During the summer I was tasked with organizing and cleaning out an old physics storage room at MIT. There were a lot of cool items for different experiments I salvaged for both Junior Lab and TSG (8.01/8.02). This is one of the items that I salvaged but it was not needed by either group, So I was able to keep it for myself.

One of the processes that is kind of casually overlooked or glanced over when looking at history is the technology of fire-hardening. In the this project I got a stick and carved a spear point on the end of it, the goal was to take a decently dried stick and create a strong staff/spear from the application of fire.

This project goal is to disassemble of a SanDisk Cruzer Fit 16 GB usb Flash Drive for purpose of gaining a low profile flash drive and learning exactly how they are built. Disassembling things gives you a good idea on how other think, and in this case on how big companies engineers think.

This project's goal was to take a old tool and refurbish it to a condition where it can be used as a fully functioning tool. The tool that spawned this project was a old shipping crate opening tool that I picked up at the MIT Swap fest, along with a drill press, a jewelers anvil, and a pickaxe head. All of which needed and still need a bit of de-rusting and cleaning up, all in their own time though (The drill press is going to be a long refurbishment project, it works but a lot of rust and parts that I want to replace/clean).

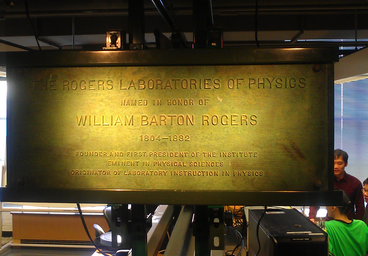

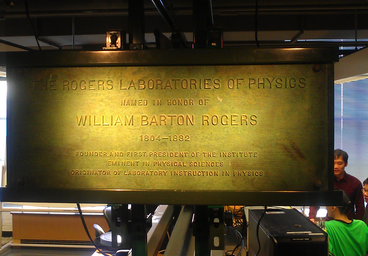

The mounting of the antique MIT lab sign (The Rogers Laboratories of Physics Sign) which is made of brass in the MIT Junior Physics laboratory. The project to mount the sign aimed to use pre-existing uni-strut frames as support and mounting surface.

A personal city transportation vehicle, A.K.A. The Hopper. This vehicle aims at being a versatile scooter that can ride both on un-kept roads, and in-doors. The current specs for this vehicle will be; 8inch diameter wheels, Capped speed of ~20 mph (Currently capped by motor controller), and an average distance of ~6.4 miles per charge (or pack).

A large framed electric scooter, The goal of this project was to create a large framed scooter. The specifications of this scooter was to create a long distance vehicle that could run on poorly maintained roads, as-well as rapidly climb large hills (tests were mainly aimed towards the steepest hill on campus *Road near E.M.P.A.C. @ RPI*). The scooter would run off of a bank of A123 battery cells (1.4Volts, 1.1 Amp hours per cell) that I would create myself. The propulsion would be a brushless motor, which original purpose would be the use in large model airplanes.

The Disassembly of a Used Wireless Handicap button to determine and understand how it works.

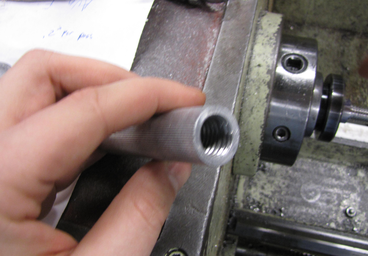

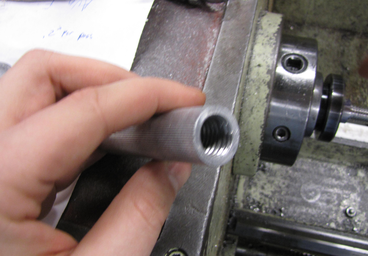

This project was used to learn how to thread using a lathe. This is an operation that is the foundation of most assembly and I thought it was a very important thing to know and understand how to do. So I came up with a simple project which requires threading, a waterproof match canister.

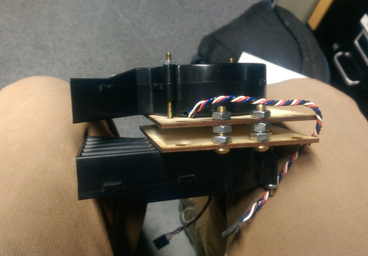

This Project outlines the simple construction of a fascinating dynamical system; a double pendulum or Chaos Pendulum. This project aims at creating a simple, cost effective and sturdy chaos pendulum for the RPI Society of Physics Students.

This Project was designed to facilitate the creation of electronic based projects without the necessity of a dedicated Lab Bench. The Goal was to design and create a basic electronics kit that allows any table to become a basic electronics bench.

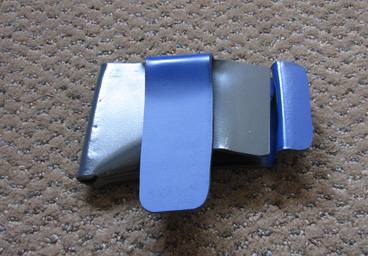

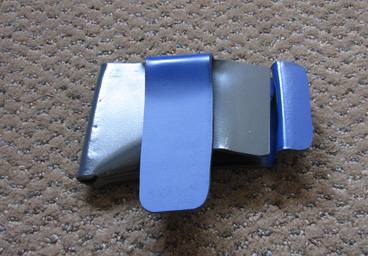

This project is one of my first major endeavors into thermal plastics. The goal of this project is to create a hatchet holder with a built-in belt clip.

This is a simple week long project where I created a wooden mount for a crowbar, which I painted to resemble a crowbar from a popular science fiction game (Half-Life).

A simple project aimed at creating a lanyard with a basic lashing using nylon string removed from the core of paracord rope.

"The use of basic machine tools such as lathes, mills, drill presses, band saws, and grinders, including micrometers, vernier calipers, and various other devices used in a machine shop or laboratory. Welding techniques and tool making are also considered." - Taken from the RPI Course Catalog

This project is a simple repair involving a salvaged laptop cooling pad. The goal of this project is to dismantle, learn how it works and create an effective repair.

This project is aimed at creating a handheld laser out of a laser diode, specifically a 405nm 100mw diode.

This project documents the many projects and personal research I worked on during my freshman year. This includes; An Electromagnet Magnet Maker, a Handheld Coilgun, and Research into: Mu Metal applications and ferrofluids.